Pg Thread Taps

Price 300 INR/ Piece

Pg Thread Taps Specification

- Cutting Force

- High

- Material

- High Speed Steel (HSS)

- Cutting Speed

- Standard threading speed

- Drill Bits Types

- Pg Thread Taps

- Operation Type

- Manual/Machine

- Cutting Accuracy

- Precision

- Cutter Type

- Thread Tap

- Coating Type

- Black Oxide

- Cutting Capacity

- Mild Steel, Aluminum, Brass, Plastics

- Tool Type

- Hand and Machine Tap

- Features

- High hardness, durable, precise threading capability, corrosion resistant

- Brooches Type

- Tap Threading

- Hardness

- HRC 58-62

- Shape

- Cylindrical

- Operate Method

- Rotational threading

- Coating

- Black Oxide

- Machine Type

- Tapping Machine, Drilling Machine, Hand Operated

- Length

- Standard PG Length

- Diameter

- PG 7 to PG 48

- Maximum Torque

- Varies by Tap Size

- Processing Type

- Thread Cutting

- Blade Size

- Standard available sizes

- Thread Pitch

- PG thread (varies by size)

- Minimum Order Quantity

- 1 Piece

- Finish Type

- Polished

- Application

- Threading holes for electrical cable glands

- Packing Type

- Box

- Use

- Electrical conduit, cable glands, and junction boxes

- Thread Standard

- DIN 40430

Pg Thread Taps Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Days

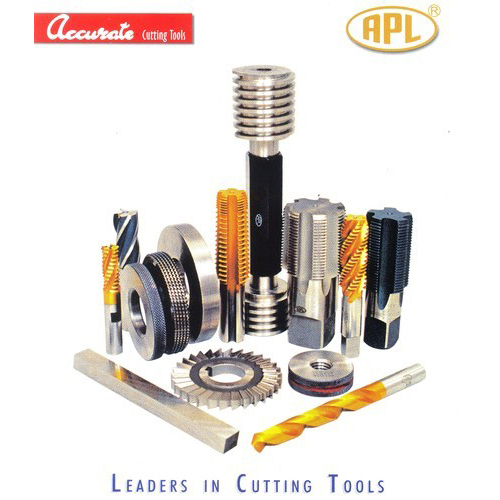

About Pg Thread Taps

On account of immense experienced in this field, we are passionately indulged in proposing a large series of superior PG Thread Taps. These kinds of taps are fitted to modern tapping machine for cutting alloy steel, stainless steel and bronze with high precision. They are fabricated from top-grade steel with accurate thread, shape, and size with developed casting technology ensures its optimum performance, rust resistance and durability. Further, clients can buy PG Thread Taps in various sizes, finishes, and grades at negotiable prices.

Specification

|

Size |

All Pg Thread Taps available |

|

Usage/Application |

For making electrical conduit threads |

|

Finishing Type |

Bright |

|

Shank Type |

Straight Shank |

|

Country of Origin |

Made in India |

Precision Threading for Electrical Applications

Designed specifically for threading holes for electrical cable glands, Pg Thread Taps ensure accurate and consistent threading in conduit fittings, cable glands, and junction boxes. Their adherence to DIN 40430 standards makes them reliable for industrial use, supporting efficient installation in structured wiring and electrical contractor settings.

Durable and Versatile Construction

Manufactured from high-quality HSS and finished with a corrosion-resistant Black Oxide coating, these taps offer long-lasting performance. Compatible with both hand and machine tapping, they effectively cut through a variety of materials, including mild steel, brass, aluminum, and plastics, accommodating diverse electrical and engineering demands.

Available in Multiple Sizes for Flexible Application

With size options ranging from PG 7 to PG 48 and standard lengths, these taps cater to a wide array of electrical conduit sizes. Their high cutting accuracy and maximum torque (variable by tap size) make them suitable for any job, whether small-scale maintenance or large industrial installations.

FAQ's of Pg Thread Taps:

Q: How are Pg Thread Taps used in electrical installations?

A: Pg Thread Taps are used to create precise threads in holes of electrical conduit fittings, cable glands, and junction boxes. After drilling the hole, the tap is inserted and rotated-either manually or by machine-to cut threads that match the size and pitch of PG threads, ensuring a secure fit for cables and connectors.Q: What materials can Pg Thread Taps effectively cut?

A: These taps are engineered to cut threads in mild steel, aluminum, brass, and various plastics. Their high-speed steel construction and sharp cutting edges allow for efficient threading across a variety of materials commonly used in electrical and fabrication work.Q: When should I choose a PG thread form over other types?

A: Select PG threads when you need to ensure compatibility with European-standard electrical cable glands and fittings. PG threading is commonly specified for projects requiring secure and reliable connections in power distribution and industrial wiring.Q: Where can these PG Thread Taps be applied?

A: They are primarily used in electrical conduit systems, cable gland installations, and junction box assemblies. Industries such as construction, electrical contracting, and manufacturing benefit from their precise threading and reliable performance.Q: What is the thread standard and range of sizes available for these taps?

A: Pg Thread Taps conform to DIN 40430, featuring PG threads with variable pitch depending on size. Available diameters range from PG 7 to PG 48, covering standard requirements for electrical and mechanical assemblies.Q: How does the Black Oxide coating benefit the tap?

A: The Black Oxide coating enhances corrosion resistance and extends the working life of the tap. It also reduces friction during use, resulting in smoother threading and better dimensional accuracy.Q: Can these taps be used with both hand and machine tools?

A: Yes, their robust design allows for efficient threading using either hand-operated tap wrenches or compatible tapping machines, supporting versatile operations in workshop and onsite environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thread Taps Category

Hss Ground Thread Taps

Price 125 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Others, HighSpeed Steel (HSS)

Cutting Force : High

Cutting Speed : Recommended for Moderate to High Speeds

Drill Bits Types : Thread Tap

Long Nut Taps

Price 365 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Others, High Speed Steel (HSS)

Cutting Force : High

Cutting Speed : Standard (dependent on material)

Drill Bits Types : Long Nut Taps

Spiral Point Plug Taps

Price 155 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Others, High Speed Steel (HSS), HSSE, or HSSCo

Cutting Force : High

Cutting Speed : Optimized for steel, alloy steel, and stainless steel

Drill Bits Types : Spiral Point Plug Tap

Bscy Thread Taps

Price 131 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Others, High Speed Steel (HSS)

Cutting Force : High

Cutting Speed : Medium to High

Drill Bits Types : Thread Tap

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry